Cross-Cutting

Clusters

Build clusters in plastics recycling, advanced manufacturing, and tech

Erie has persevered through a considerable post-industrial decline. While many old jobs have disappeared, much of the infrastructure, systems, and human capital remain in Erie, creating a unique opportunity to revitalize the economy for the 21st century. A group of stakeholders from PSU and Gannon have come to together with a plan for a set of investments in advanced manufacturing, plastics recycling, and the blue economy. These investments, if completed, could create up to 5,000 jobs and make Erie the epicenter of nationally competitive industries. If these projects are appropriately staffed, resourced, and implemented, they could reverse decades of decline and begin a new chapter for Erie’s economy.

To provide skilled, higher paying jobs and a competitive new cluster of businesses in a set of related industries that leverage the unique assets and history of Erie and the surrounding county. The emerging plastics recycling cluster in Erie creates opportunities to research sustainable plastics in Lake Erie and test new clean transportation technology required for plastics recycling.

1.1: Create centers for manufacturing competitiveness, including heavy industrial battery testing and microplastic pollutant mitigation

![]()

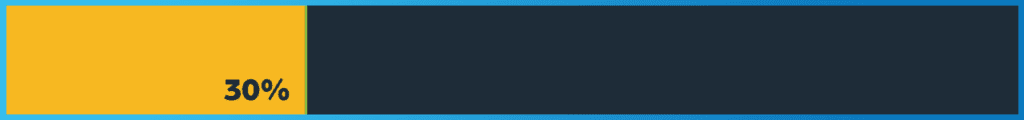

Investment Overview:

A center of manufacturing competitiveness could provide the capability to transition to a sustainable economy in the areas of plastics recycling, metal casting, and tail transportation. The center would include an advanced polymers and materials lab to design more sustainable and recoverable plastics as well as metal castings labs for prototyping and a heavy industrial battery testing facility to design zero-emission long-haul transportation.

![]()

Goals and Benefits:

The center for manufacturing competitiveness will help create ~5,000 jobs in the advanced manufacturing and plastics sectors. The center will also lend to increasing wages, union representation, reducing plastic waste locally and globally as well as expanding access to related utilities, such as broadband, that would be created in the area.

![]()

Relevant Examples:

Nussbaum Center and Steel house project in Greensboro is an urban innovation center designed to reduce barriers for manufacturing entrepreneurs.

![]()

Cost, Sources, and Uses:

Total cost: $56,000,000

$14M - Building (KP 8)

$12M - Lab equipment and operation

$20M - Battery facility and lab equipment

Sources: Future BBB RC programs, City and State ARPA funds

![]()

Progress and Next Steps:

- Identify final breakdown of costs

- Secure additional state and federal funding opportunities

1.2: Create sustainable plastics practices by investing in new recycling plants and technologies

![]()

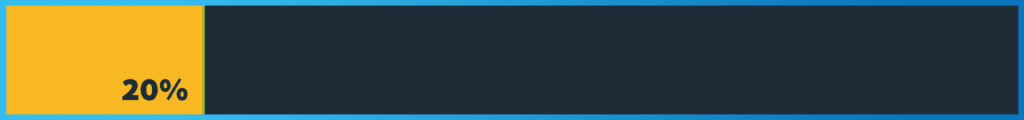

Investment Overview:

This sustainable plastics project will leverage the sustainable plastics work of the Center for Manufacturing Competitiveness to create an environment for sustainable agriculture. A Plant-to-Plants Lab will capture heat, carbon dioxide, and moisture from manufacturing efforts at the Center to power a pilot food production project. The foods grown will be influenced by and distributed to underrepresented communities in the region. The lab will be built in a “kit” form, complete with a list of equipment, cost estimates, space layout, and expected ROI, to allow for easy extension to manufacturing sites in coal-impacted areas to address food deserts in their own communities.

![]()

Goals and Benefits:

- Increase sustainability of advanced manufacturing by recycling byproducts into local agriculture

- Use plant-to-plants lab as a model for the circular economy that can be exported across the region / country

![]()

Cost, Sources, and Uses:

Total cost: $5,000,000

$2.5M - Recycling line

$0.5M - Personnel

$2.0M - Equipment

Sources: TBD

![]()

Progress and Next Steps:

- Finish plans for plant-to-plants lab

1.3: Create centers for Great Lakes health monitoring and nano-particle science testing and education

![]()

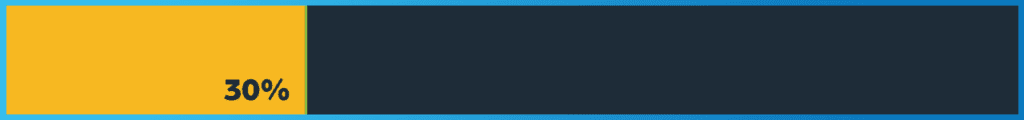

Investment Overview:

Lake Erie would be leveraged as the testbed for evaluating plastic pollution and measuring manufacturing investment effectiveness as manufacturers move toward a circular economic model. Located at Gannon and along the waterfront, these labs would conduct environmental testing, drone-based monitoring, and geospatial mapping to conduct research on environmental changes to the lakes. They would also map plastics pollution and provide data for better environmental cleanup of plastic-polluted bodies of water.

![]()

Goals and Benefits:

Along with the center for manufacturing competitiveness, the Great Lakes testing lab will help create ~5,000 jobs in the advanced manufacturing and plastics recycling sectors while also increasing wages, union representation, reducing plastic waste locally and globally, and expanding access to related utilities, such as broadband, that would be created in the area.

![]()

Cost, Sources, and Uses:

Total cost: $41,000,000

$7M – Deepwater science ship

$4M – Near-shore boat and equipment

$5M – Docking facility and pit stop lab

$10M – EPA/CLIAA-certified lab

$5M – Neural drone lab for GIS-mapping

Sources: TBD

![]()

Progress and Next Steps:

- Identify final breakdown of costs

- Secure additional state and federal funding opportunities

1.4: Create CATCH Hub in Corry

![]()

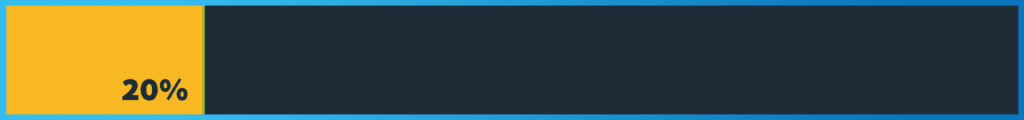

Investment Overview:

Impact Corry, a part of Project Resolve, is an effort to build a state-of-the art technology workforce, training, entrepreneurship ecosystem and launchpad. The building, located in Corry, will house a technology workforce & remote training & placement center, a technology and wellness Pre-K Educate Center, a coworking space, office space, media studios, a data center, and entrepreneurial support space (e.g., coffee center, gym, cafeteria). Initially, the CATCH Hub will focus on housing projects and businesses related to broadband expansion, given considerable activity currently taking place in Corry already.

![]()

Goals and Benefits:

Along with the center for manufacturing competitiveness and other investments in clusters in the Erie area, the CATCH Hub will be a center for post-pandemic technology businesses, startups, and trainees outside of Erie’s downtown.

![]()

Cost, Sources, and Uses:

Total cost: $18,000,000

Uses:

$18M –Building renovation and upgrades

Sources:

$1.58M –Facility donation

$2.5M –PA RACP

$185k –ECRDA $500k –Federal community project funds

$13.2M –TBD

![]()

Progress:

Identify location and secure site control

Build partnerships with Penn State Behrend, Gannon, other regional organizations focused on cluster development

Identify pilot industry

Next Steps:

Secure additional funding to renovate and upgrade facility

Apply for other federal grants (e.g., NSF Engines)

Launch pilot in fiber / connectivity industry